Vitrion

Precision Glass Processing Service

We unlock the full potential of glass for microsystems technology

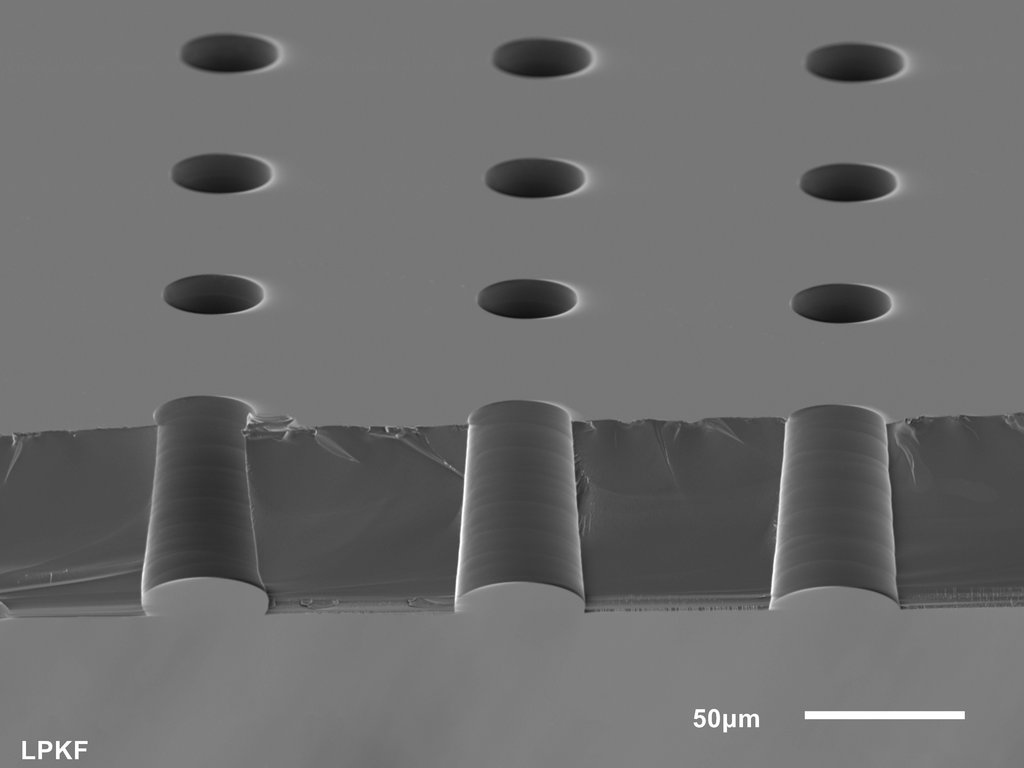

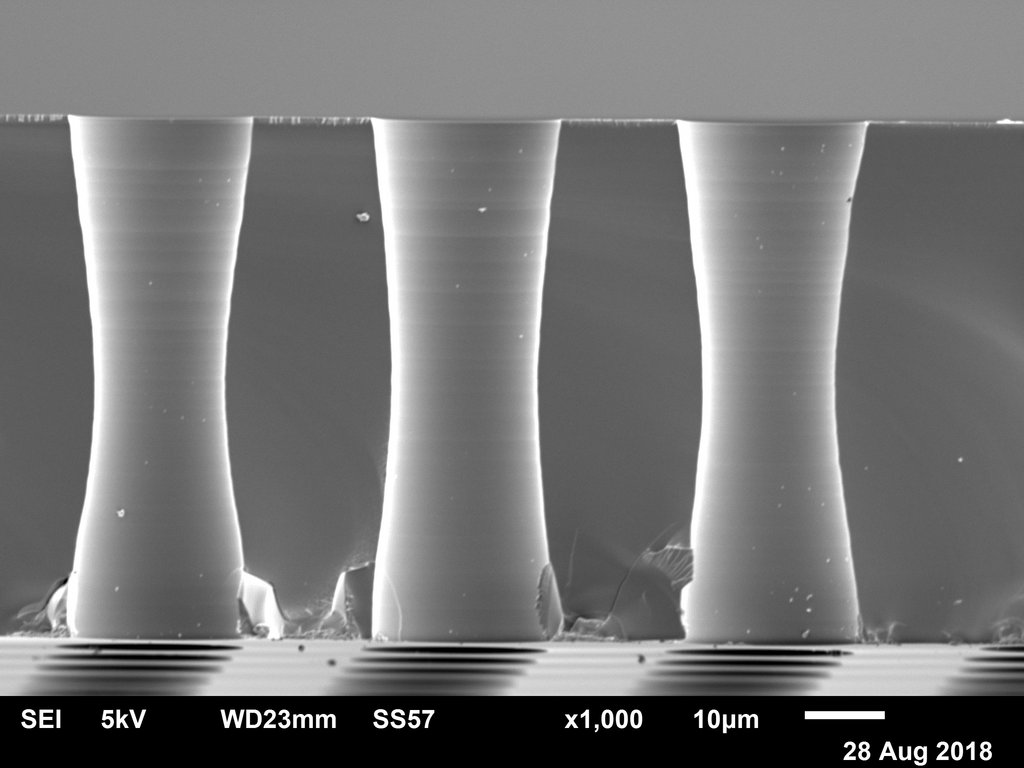

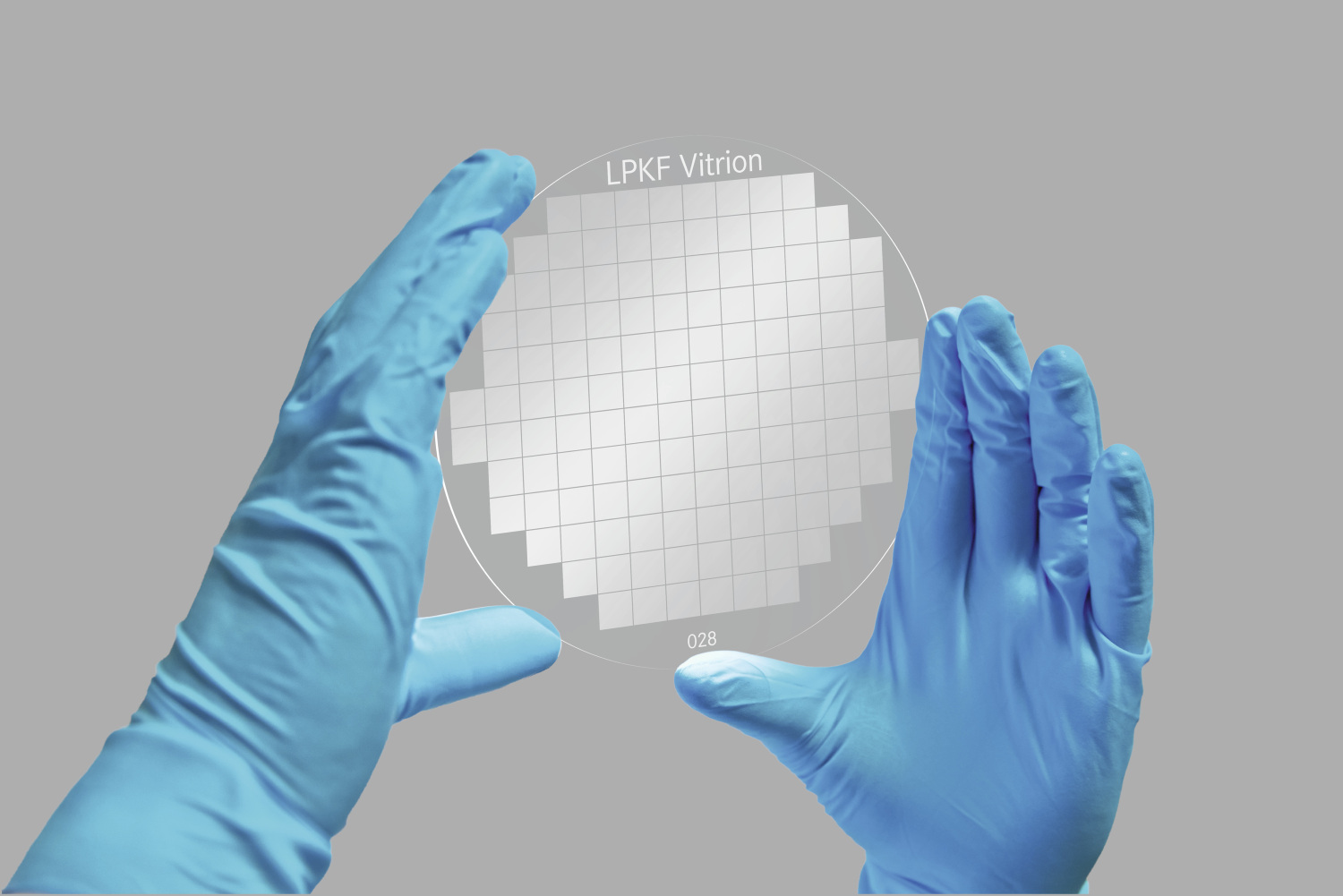

Did you know that LPKF now offers a foundry service for thin glass substrates? Recently, LPKF introduced the Laser-Induced Deep Etching technology, or LIDE for short, a process for the precise and highly efficient manufacturing of through-glass vias (TGV) and other deep micro features in thin glass substrates. The innovative LIDE process has overcome past limitations in glass drilling and micro machining as it combines very high productivity and low manufacturing cost with the superior quality of a direct data process, forgoing masks or photo processing.

With the introduction of its new independent foundry service, LPKF is hoping to make the LIDE technology more flexible and accessible for a variety of purposes, such as prototyping and experimental applications as well as scalable mass production capacity.

The service is ideal for manufacturing glass substrates for advanced IC and MEMS packaging as well as micro-machining spacer wafers, microfluidics and other specialty glass applications. LPKF's new foundry service is located at its corporate headquarters and will operate under the company's Vitrion brand name.

Visit www.vitrion.com to learn more.

Micro-Machining of Thin Glass for Innovative Applications

Micro-Machining of Thin Glass for Innovative Applications