Processing Rogers Bonding Materials with LPKF Prototyping Equipment

RF technology faces increasingly discriminating standards for miniaturization and short design cycles. Because of this, finding reliable, efficient prototyping processes has become more important than ever, with multilayer applications presenting an ever bigger challenge. In-house PCB prototyping, however, offers a series of intriguing benefits for RF research and development. Engineers can go from design to finished prototype in a matter of hours, make design revisions easily via machine software, and maintain complete user control over the prototyping process. When it comes to multilayer applications, the design will be milled or etched onto the surface of the board, the layers will be pressed together, and through-holes will be drilled and then plated to complete a functional multilayer structure.

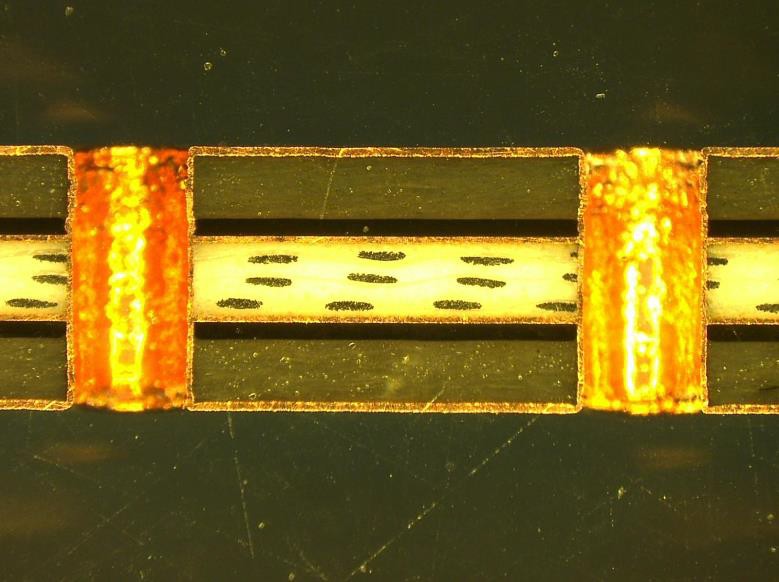

This paper examines creating and measuring the quality of a multilayer PCB made with LPKF in-house PCB prototyping equipment.