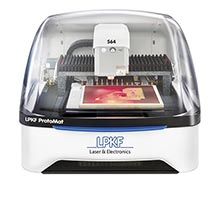

ProtoMat S64

The Standard for Rapid PCB Prototyping

LPKF ProtoMat S64 – The Standard for PCB Prototyping

- Fully automatic operation including automatic tool change

- Low-maintenance, high-speed milling spindle

- Intuitive, integrated system software

- Fiducial recognition camera and milling depth/width control

- Granite base for high accuracy

The ProtoMat S64 demonstrates speed and reliability, setting the standard for almost all in-house PCB prototyping applications. The high-speed of the low-maintenance milling motor guarantees production of fine structures as small as 100 μm (4 mil) and multilayer boards can be achieved when used in conjunction with a lamination press. A high precision ceramic vacuum table is also standard to help hold materials flat. An optional solder paste dispensing adaptor can also be added to prepare for component population. The ProtoMat S64 is a perfect addition to any development environment.

60,000 RPM Spindle Motor

The milling spindle with 60,000 RPM guarantees the shortest machining times and highest geometric accuracy. It is low-maintenance due to the new pneumatic self-cleaning function for the motor and milling depth sensor. The granite machine base also ensures consistently accurate results.

Tool Change, Milling Depth/Width Adjustment, and Dispensing are Automatic

Up to 15 tools – more if required – can be changed automatically during the production process. Depending on the depth, the conical milling cutters generate different insulation channels. Additionally, the automatic milling width adjustment ensures that the milling contour has a constant width. These features shorten the setup time and enables operator-free performance.

Sensors in the ProtoMat S64 ensure optimally controlled, exact milling depth and monitor the tool change process.

Housing parts can be machined in up to 2.5 dimensions. If required, the integrated dispenser can automatically apply solder paste to solder pads. Additional data calculation is not necessary.

Integrated, Intuitive Operating Software

The ProtoMat system software is highly flexible and easy to use. A parameter library for different materials supports the easy machine operation. If required, the integrated process guide leads the user step by step through the machining process.

Technical Specifications: ProtoMat S64 |

|

| Max. Material size and layout area (X/Y/Z) | 229 mm x 305 mm x 43 mm (9” x 12” x 0.3”) |

| Mechanical resolution (X/Y) | 0.5 μm (0.02 mil) |

| Repeatability | ± 0.001 mm (± 0.04 mil) |

| Milling spindle | Max. 60 000 RPM, software-controlled |

| Tool change | Automatic, 15 positions |

| Milling width adjustment | Automatic, micro switch ± 1 μm (0.04 mil) |

| Tool holder | 3.175 mm (1/8”) |

| Drilling speed | 100 strokes/min |

| Travel speed (X/Y) | 150 mm/s (6”/s) |

| X/Y-drive, Z-drive, tool feed | 3-phase stepper motor, 2-phase stepper motor, 2-phase stepper motor |

| Solder paste dispense rate | ≥ 0.3 mm (≥ 0.011”) (solder point), ≥ 0.4 mm (≥ 0.015”) (pad) |

| Dimensions (W x H x D), weight | 680 mm x 560 mm x 800 mm (26.8” x 22.0” x 31.5”), 95 kg (210 lbs) |

| Operating Conditions | |

| Power Supply | 90–240 V, 50–60 Hz, 450 W |

| Compressed Air Supply | 6 bar; 35 l/min (90 PSI @ 1.25 CFM) |

PDF download

Quick Comparison

PDF download

PDF download

Which system is best for you?