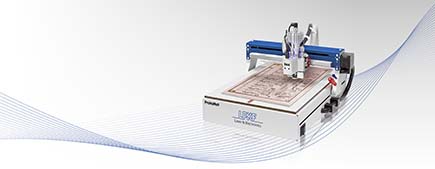

ProtoMat E44

For Machining Circuit Boards in Training and School

The LPKF ProtoMat E44 rapid PCB milling system is a low-cost introduction to the world of professional in-house printed circuit board prototyping. Structure single or double-sided circuit boards, drill holes for through-plating and cut individual boards from the base material with a full 9" x 12" working area.

The LPKF ProtoMat E44 provides a variable spindle motor with up to 40,000 rpm for clean copper edges. The maximum travel speed is up to 100 mm per second and a quick manual tool change allows simple operations. Cut depth control is maintained even with variations in the PCB substrate thickness with the included auto-adjusting depth limiter foot. Precision cut depth adjustment is also enabled with the included micrometer screw.

With mechanical resolution of less than 1 μm, repeat accuracy of ± 5 μm, and precision of ± 20 μm for double sided alignment, these compact benchtop ProtoMat circuit board plotters enable rapid prototype PCB milling with traces as small as 4 mil (0.1mm) and spacing of 6 mil (0.15mm) or larger.

Registry System and Camera

In addition to increased positioning accuracy with double-sided printed circuit boards, an automated fiducial alignment camera is provided on the ProtoMat E44 model. The camera measuring function enables a desired cut width to be set more easily with the ProtoMat E44.

The E44 also allows for set pin registry for processing double-sided printed circuit boards. They hold the processed circuit boards securely in position, even after the boards are turned over for structuring the second side. With the E44, the camera improves alignment positioning as it detects fiducials or geometric structures and orients the structuring process accordingly within the software.

Software Package

LPKF CircuitPro software is included with easy to follow processing guide wizards and updated GUI. This simplifies the process of arriving at a completed design with the machine prompting the operator during each milling, drilling and cutting stage. A comprehensive parameter library for many commonly used materials supports the users in their own projects.

ProtoMat Engineering

The LPKF ProtoMat PCB milling systems utilize the highest quality stepper motors, spindle motors and H-shaped guide rails mounted to a durable frame to ensure pristine milling, drilling and cutting quality for years of operation. Spindle runout below 5µm and an internal calibration completed on each machine is standard with over 40 years of German engineering experience applied in development of each model.

ProtoMat E44 |

|

| Max. material size andlayout area (X x Y x Z) | 229 x 305 x 5 mm ( 9” x 12” x 0.2”) |

| Travel speed diagonal (X x Y) | 100 mm/s (3.9”/s) |

| Milling spindle | Max. 40 000 rpm |

| Drilling speed | 100 holes/min |

| Tool holder | 3,175 mm (1/8”), manual tool change |

| Repeatability | ± 5 µm (± 0.2 mil) |

| Mechanical resolution (X/Y) | ± 0.8 µm (± 0.04 mil) |

| Accuracy in the fitting hold system | ± 20 µm (± 0.8 mil) |

| Resolution camera | 1.3 Mpx |

| Dimensions (W x H x D) | 370 x 300 x 450 mm ( 14.6” x 11.8” x 17.7”) |

| Weight | 15 kg (33 lbs) |

| Ambient temperature | 15 °C - 25 °C (59 °F - 77 °F) |

| Power supply | 100 - 240 V, 50 - 60 Hz, 120 W |

| Required USB ports | 2 |

| Required accessories | Exhaust unit |

PDF download

Quick Comparison

PDF download

PDF download

Which system is best for you?