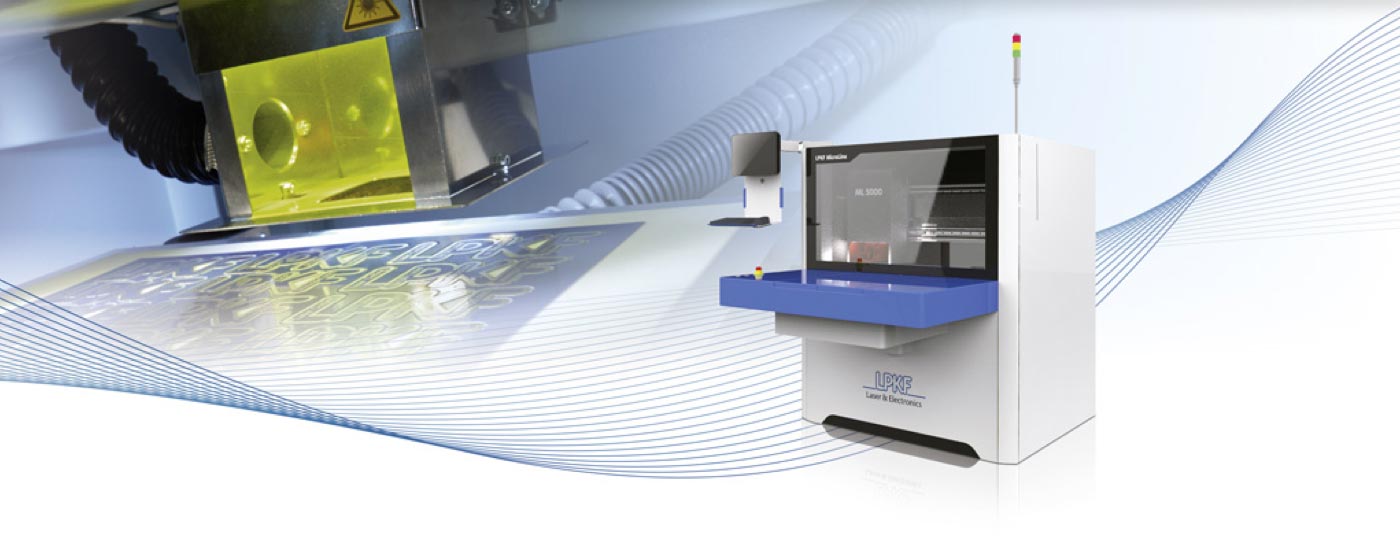

MicroLine 5000

State of the Art in Laser Processing of Flex PCBs

LPKF MicroLine UV laser systems don’t compromise quality or precision over cost-efficiency. These three principles, which are critical to any manufacturing operation, are the driving force behind the development of the MicroLine 5000 series UV lasers systems from LPKF for the drilling and cutting of flexible PCBs.

Unsurpassed Drilling Performance

The MicroLine 5000 is the flex PCB industry’s answer to high through-put, high-yield drilling applications. With the ability to drill holes down to 20 μm, a variety of both organic and inorganic substrates can be processed such as:

- Flexible PCBs

- IC substrates

- High Density Interconnect PCBs

Common applications include the drilling of through holes and blind vias, with the additional ability to cut large mounting holes, or full perimeter cuts of irregular board contours.

Quality and Precision

The high-quality attributes of the UV wavelength allow for the cutting and drilling of delicate materials with minimal heat affected zone – and the proof is in the results: clean side-walls with precise dimensions and virtually zero debris. Available with either a 10 W or 15 W laser source, the MicroLine 5000 series may also be configured to work with various material handling options.

Contour Cutting

The MicroLine 5000 UV laser is a universal tool – and thus suitable for cutting all industry-standard panel sizes with dimensions of up to 21” x 24” (533 mm x 610 mm). The 20 μm high quality UV laser kerf width allows for cutting of even the most delicate contours at high speeds.

Process Monitoring

The MicroLine 5000 systems are equipped with an integrated vision system for fast fiducial recognition, ensuring accurate alignment. The camera’s ability to use virtually any board feature as a fiducial alignment point provides operator flexibility from job to job.

In addition, an integrated power measurement system at the work surface ensures reliable, repeatable control.

Technical Specifications: MicroLine 5000 |

|

| Laser Class | 1 |

| Max. Working Area (X.Y.Z) | 533 mm x 610 mm x 11 mm (21” x 24” x 0.43”) |

| Max. sheet size; max. reel width | 533 mm x 610 mm (21” x 24”); 500 mm (19.6”) |

| Max. structuring speed | Depends on application |

| Positioning accuracy | ± 20 μm (0.8 mil) |

| System dimensions (W x H x D) | 1660 mm x 1720 mm x 1900 mm (66” x 68” x 75”); height incl. StatusLight = 2200 mm (87”) |

| Weight | ~2000 kg (4,400 lbs) |

| Operating Conditions | |

| Power Supply | 400 VAC, 3-phase, 50-60 Hz, 16 A, 7 kVA |

| Cooling | Air-cooled (internal water-air cooling) |

| Ambient temperature | 22° C ± 2° C (72 °F ± 4 °F); |

| Humidity | <60% (non-condensing) |

| Required Accessories | Exhaust unit fume excraction + Filtration unit |

PDF download