PowerWeld3D 8000

Laser Plastic Welding in a New Dimension

You are here: Products > Laser Plastic Welding > PowerWeld3D 8000

New technology advances the manufacturability of the latest OEM automotve lighting design requirements

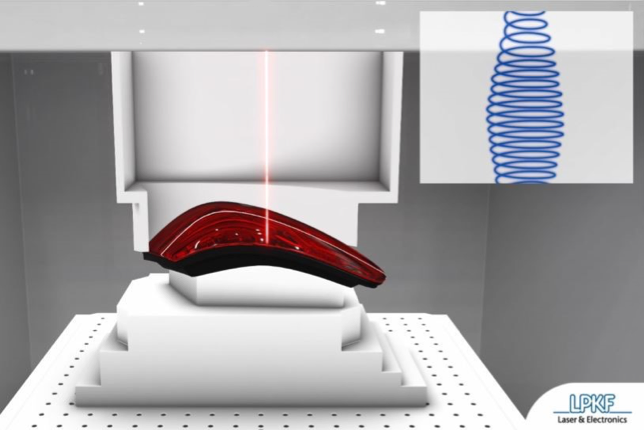

LPKF introduced exciting new technology for welding complex 3D shaped parts like auto- motive tail lights and exterior and interior trim panels.

What’s Driving the technology?

- “Glaskante" - Illumination to the edge

- Increasing use of rear combined lamps (RCL)

- Increasing use of Skin Molding lenses (esp. VW-group)

- Tighter tolerances

- Reduction of unilluminated surrounding area

- Incorporation of weld seam as a visible design element

- Cost reductions by reduced scrap rate and 33% faster cycle times

- Faster time to market coupled with lower development costs

LPKF 3D Weld Technology

Wobble welding is a unique feature of the system, incorporating the quasi-simultaneous method with the ability to automatically control the width of a weld seam with a particularly homogeneous temperature profile, depending on the 3D contour of the lens. This leads to a 33% reduction in cycle time and the ability to monitor the quality of the weld in real time.

New, intelligent, ProSet3D software automatically determines and sets up the process parameters in minutes compared to days, allowing greatly reduced development times that lead to faster time to market.

Technical Specifications: PowerWeld3D 8000 |

|

| Laser class | 1 |

| Laser parameters | Power: 400 W, Spot: 1 mm - 5 mm |

| Clamping pressure range | Up to 20 kN |

| Max. working area (W x D x H) | 1000 mm x 750 mm x 400 mm |

| MWelding machine dimensions (W x D x H) |

1800 mm x 1700 mm x 3600 mm |

| Power Supply | 400 V, 32 A |

| Compressed air | 6 bar |

| Weight | ~ 2500 kg |

| Ambient temperature | 18 °C - 35 °C |

Technical specifications subject to change.

International Inquiries Click Here

PowerWeld3D 8000 Datasheet

PDF download

PDF download

Laser Plastic Welding Design Guidelines Manual

PDF download

PDF download