Breadboarding

What is Breadboarding?

The term Breadboarding refers to an early form of point to point construction used to build simple demonstration circuits on a convenient wooden base. This wooden base was similar to a cutting board. Traditional Breadboarding is a reusable solderless device used to build a prototype of an electronic circuit and for experimenting with circuit designs. This type of Breadboarding is time consuming and costly.

How do LPKF products take Breadboarding to the next level?

Time to market and tough design criteria are challenges that companies face in the development cycle of new products. LPKF ProtoMat systems have capabilities beyond generic Breadboarding systems. These capabilities include:

- High Quality Printed Circuit Cards

- Tight Circuit Geometry

- Controlled Trace Lengths

- Precise Component Mounting

- Proper Dielectric Material

LPKF ProtoMat systems produce printed circuits that accurately simulate the finished product. This guarantees that the rigorous testing performed on these prototype circuits will give real time results and fewer delays in the design cycle. A variety of electronic systems may be prototyped by using breadboards, from small circuits to complete central processing units (CPUs).

Which LPKF products help facilitate the Breadboarding process?

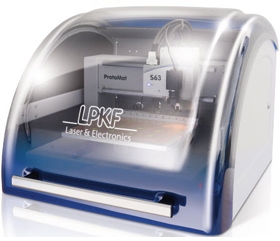

The desktop LPKF ProtoMat milling machines facilitate faster more efficient breadboarding for design work. These systems have become a standard in the industry with installations worldwide. Depending on the complexity of the design some prototypes can be produced in a matter of minutes, while more complex designs may take a few hours. In contrast, the lead times for outsourcing these designs are usually measured in weeks.

The desktop LPKF ProtoMat milling machines facilitate faster more efficient breadboarding for design work. These systems have become a standard in the industry with installations worldwide. Depending on the complexity of the design some prototypes can be produced in a matter of minutes, while more complex designs may take a few hours. In contrast, the lead times for outsourcing these designs are usually measured in weeks.

How can I get more information?

Visit http://www.lpkfusa.com/products/pcb_prototyping/machines/ for more information

Or send an email to sales@lpkfusa.com to receive a call from one of our engineers.

Which system is best for you?