Board Router

What is a Board Router?

A board router is a milling machine used for the shaping of solid materials. Its basic form is that of a rotating cutter which rotates about the spindle axis, and a table to which the workpiece is affixed. The cutter and workpiece move relative to each other, generating a toolpath along which material is removed. The movement is precisely controlled. Board routers may be manually operated, mechanically automated, or digitally automated via computer numerical control (CNC)

Why are LPKF Board Routers better than the competitions?

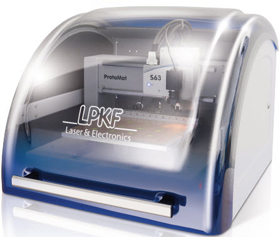

The LPKF board router product is named the ProtoMat. Using the ProtoMat system for in-house prototyping reduces your products time to market by:

- Reducing expensive R&D time

- Eliminating prototype outsourcing

- Providing in-house prototyping without chemicals

- Producing accurate “finished product” prototypes

- Providing intellectual property protection

- Decreasing iteration time

- Allowing easy exploration of new ideas

Fast turn-around time – The LPKF Board Router advantage

Many customers value the benefit of the extremely fast turn-around of their prototypes. This helps them reduce R&D time, and get their product to market faster than their competition. As most designers and group managers will tell you, the ability to maintain momentum during a development project is absolutely critical. With a LPKF Board Router designers can have PCBs and/or multilayer sub-circuits tested and re-designed with multiple prototype iterations before the end of one business day.

LPKF Board Routers can reduce development costs

Another very important “value” of the LPKF Board Router, is its ability to reduce development costs. As you know, outsourcing prototypes can be a large expense for small and large organizations alike. When you compare the cost of board material and tooling for boards made with the LPKF equipment to outsourcing, the LPKF system pays for itself after just a few projects.

Expect precision, accuracy and quality from LPKF products

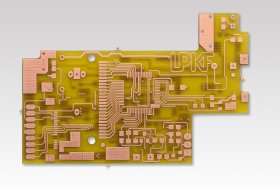

Other customers value the LPKF Board Router for its accuracy and quality of work. The quality of board produced by the ProtoMat is equal to the quality of outsourced boards and far surpasses the poor quality boards derived from in-house chemical etching. With an LPKF system, our flat bottomed end mills make a perfect 90 degree angle from the side of your trace to top of your substrate material. This is a particular benefit to RF and Microwave engineers who need that “clean” edge for accurate results.

Maintaining security – Protect your product design

Some of our customers including government agencies, defense contractors, and highly competitive industry leaders value our equipment as a means of maintaining security over their product designs. By keeping the entire development process in-house, there is an assurance in knowing that your new design has never left the building.

Rework made easy by the LPKF Board Router

Another very important aspect of electronic design and the corresponding “value” of the LPKF Board Router is its ability to rework existing PCBs. LPKF has saved many companies from a bad production run. It is also especially important for RF and Microwave engineers who use the LPKF Board Router to trim and tune their filters and antennas to the exact frequency they need. The process of iteration is reduced to hours rather than weeks.

Promote innovation and creativity – Buy a LPKF Board Router

Probably the most overlooked “value” of the LPKF Board Router is the machine’s promotion of innovation and creativity. When you have the ProtoMat system, it is far easier to “just give it a shot” when a new idea comes to mind. The easier, faster, and more convenient it is to explore a new idea, the quicker you can progress with your new technology.

As you can see, the “value” our customers place on the ProtoMat system differs as much as our customers themselves. That’s why LPKF provides 12 ProtoMat models from entry level to automatic and laser hybrid systems. Regardless of the size of your organization, with the combination of any or all of the “values” discussed above, the LPKF ProtoMat becomes an invaluable engineering tool.

How can I get more information?

To learn more about our family of rapid PCB prototyping, head over to our PCB prototyping section.

Which system is best for you?